Zerma machines installed in Gauteng, KZN

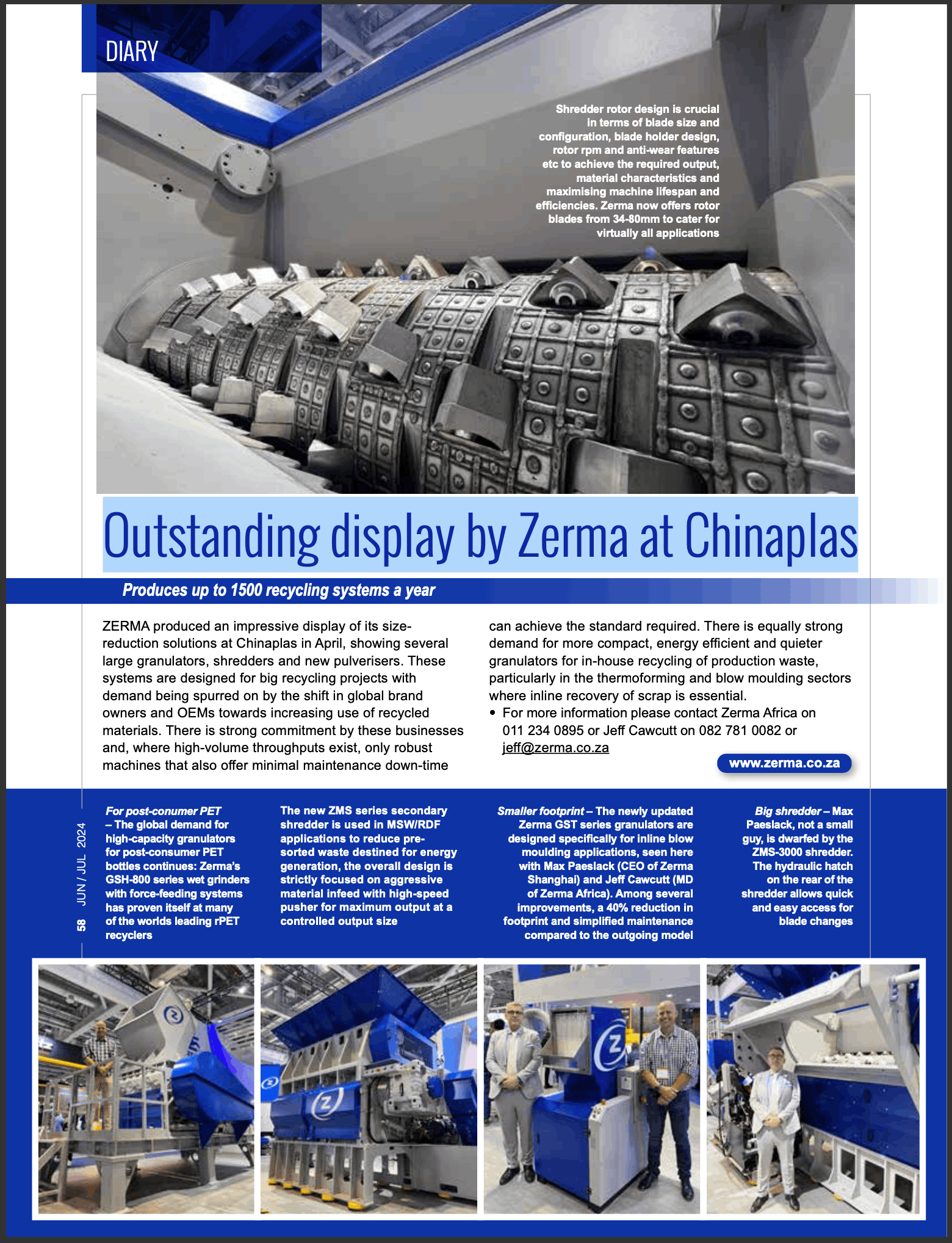

ZERMA Africa has had several busy months recently with the commissioning of machines in Gauteng and KwaZulu-Natal. At Nampak Liquid Packaging in Westmead, KZN, the granulation of large 5-litre motor-oil containers required a machine with specifi c characteristics to ensure the containers are readily accepted and recycled without bridging. The new Zerma compact GST-400/600 soundproofed granulator is designed with blowmoulders in mind. With its extremely tangential cutterhouse design and overall robust construction, it handles both the containers and heavy fl ash with ease. Tuffl ex Plastic Products commissioned a Zerma ZXS-2000 heavy-duty single-shaft shredder. To reduce a wide variety of challenging material at high capacity, from large lumps and lengths of thick pipe, to film and woven PP material and almost everything in between, Tuffl ex required a versatile heavy-duty shredder – the Zerma ZXS series single-shaft shredder met the brief.

Meanwhile, three Zerma GSE-500/500 granulators were recently installed in Gauteng at a world-class manufacturer of containers for the chemical and edible oil market. The choice of granulator for 25 litre jerry cans can often be a compromise between recycling the lightweight, voluminous containers and the thick, cold tops and tails; not so with Zerma’s GSE series cutterhouse design and rotor configuration.

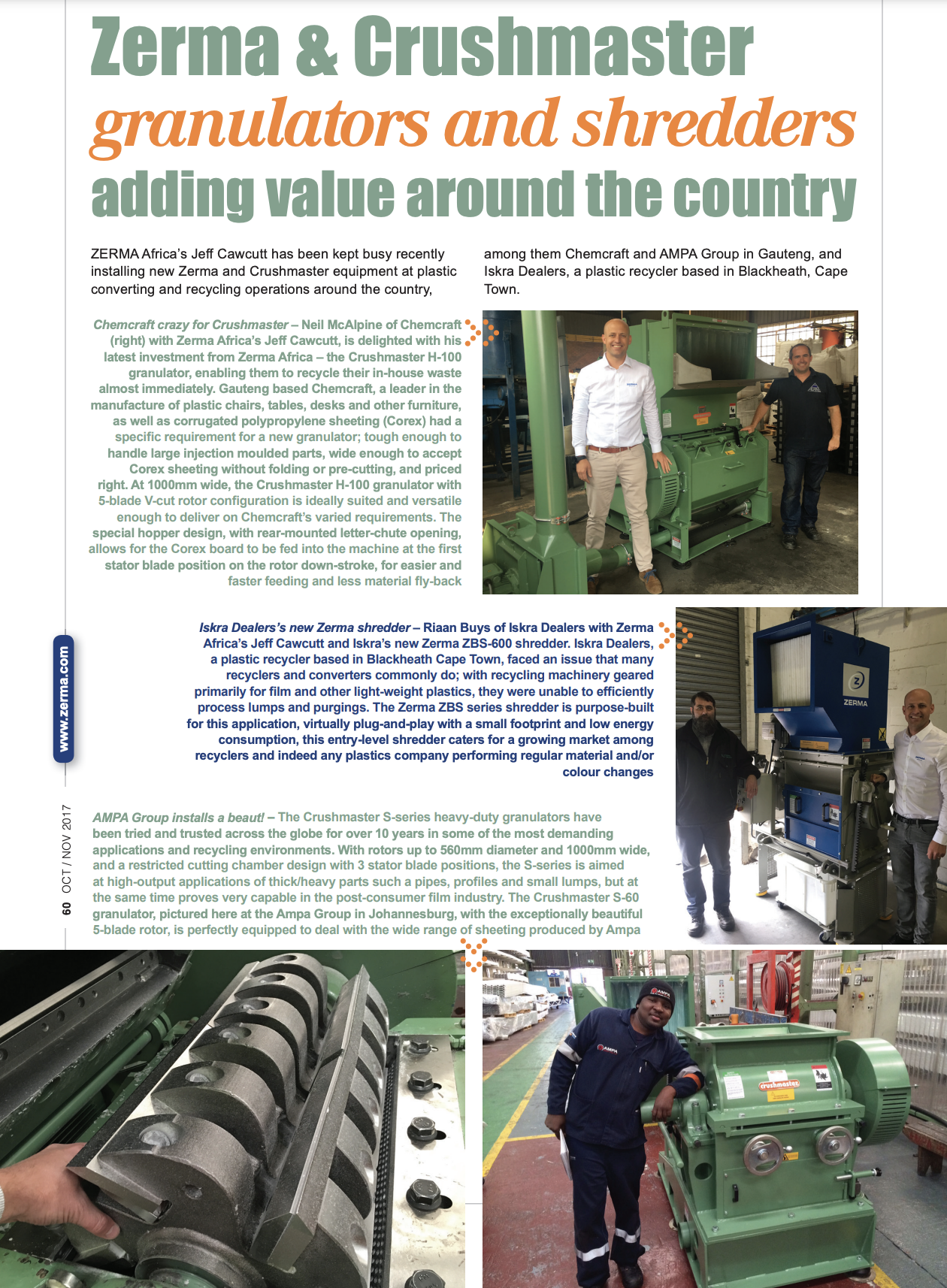

“Quick and easy access to the machine makes for rapid material changes, and the blade fi tting jig means less machine downtime with the setting done externally”, says Zerma Africa’s Jeff Cawcutt.